В современную стремительную цифровую эпоху потребность в охлаждении в центрах обработки данных и серверных комнатах постоянно растет. Обеспечение эффективной и стабильной работы оборудования зависит от тщательного выбора прецизионных кондиционеров. Однако различные типы и технические характеристики прецизионных кондиционеров могут сделать сложной задачу четкого формулирования требований к охлаждению при запросе предложений.

В этой статье мы используем многолетний опыт выбора и проектирования прецизионных систем кондиционирования воздуха для клиентов. Мы стремимся предоставить ключевые аспекты выбора прецизионных кондиционеров в критических условиях с точки зрения клиентов, чтобы улучшить ваше общение с производителями или другими поставщиками в отношении ваших потребностей в прецизионном кондиционировании воздуха. Если вы не знакомы с продуктами прецизионного кондиционирования и обеспокоены тем, как точно описать свои требования, что может привести к неудовлетворенным потребностям, мы рекомендуем вам продолжить чтение, чтобы подготовиться к будущим обсуждениям.

Как работает прецизионный кондиционер?

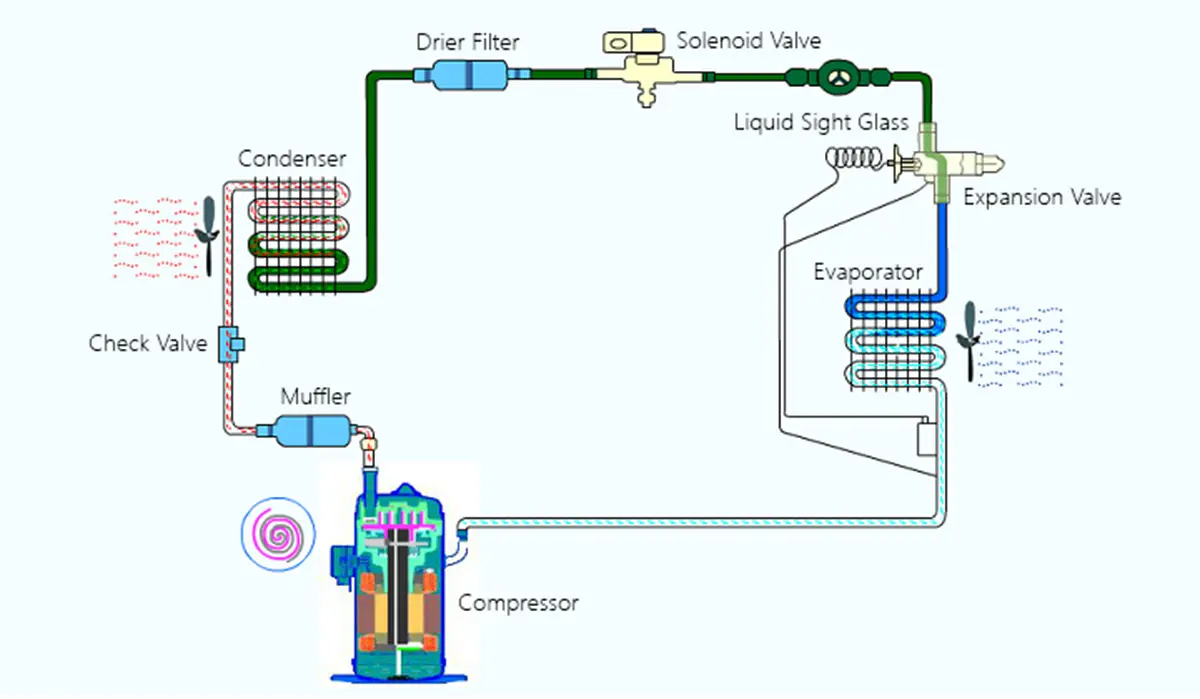

Прежде чем мы начнем обсуждать, как выбрать подходящий PACs, будет полезно дать обзор основных принципов его работы. Как показано на следующем рисунке, принцип работы стандартной прецизионной системы кондиционирования с воздушным охлаждением можно описать следующим образом:

- Компрессор: Цикл начинается с компрессора, который всасывает газообразный хладагент низкого давления (около 12°C) и сжимает его в газ высокого давления и высокой температуры (около 80°C).

( Как именно сжатие повышает температуру? ) - Конденсатор: Газ под высоким давлением поступает в конденсатор, где он отдает тепло благодаря охлаждающему действию вентилятора и конденсируется в жидкость под высоким давлением с температурой окружающей среды (около 35°C).

- Расширительный клапан: Конденсированный жидкий хладагент проходит через расширительный клапан. Внутри расширительного клапана хладагент подвергается снижению давления, что приводит к падению температуры, превращаясь в жидкость с низким давлением и низкой температурой (около 7°C).

- Испаритель: Низкотемпературный жидкий хладагент поступает в испаритель, поглощает тепло из окружающей среды (например, из помещения), превращаясь в газ низкого давления, тем самым достигая эффекта охлаждения.

- Цикл: После испарения газообразный хладагент возвращается в компрессор (температура возвращается примерно к 12°C), завершая цикл.

Определите потребность в охлаждении

После того как вы определились с методом охлаждения для вашего прецизионного кондиционера, необходимо указать конкретные требования к охлаждающей нагрузке.

Во-первых, если у вас уже есть конкретные данные о потребностях в охлаждающей нагрузке, вы должны сообщить их непосредственно производителю, чтобы убедиться, что выбранный кондиционер имеет холодопроизводительность, равную или превышающую ваши требования.

Во-вторых, если у вас нет четких спецификаций нагрузки на охлаждение, вы можете оценить ее, исходя из общей нагрузки на серверную комнату. Для этого необходимо произвести расчеты на основе размера помещения и тепловой мощности оборудования, используя следующие формулы:

- Расчет нагрузки на охлаждение помещения:

Нагрузка на охлаждение помещения = Площадь помещения × 0,2 кВт/м²

- Расчет тепловой мощности оборудования:

Тепловыделение оборудования = (Общая нагрузка оборудования в шкафу кВт или мощность ИБП) × 0,8

- Альтернативный расчет нагрузки на охлаждение:

Если информация о нагрузке недоступна, нагрузку на охлаждение можно рассчитать следующим образом:

Нагрузка на охлаждение = Площадь помещения × (0,35 - 0,5) кВт/м²

Понимание этих формул расчета не является обязательным; производители выполнят эти расчеты, как только получат достаточную информацию. После того как вы получили необходимую мощность охлаждения, пришло время выбрать типы и характеристики прецизионных кондиционеров, которые будут соответствовать вашим требованиям.

Поймите методы охлаждения прецизионных кондиционеров

После того как вы получили расчетную мощность охлаждения для вашего IT-пространства, пришло время выяснить, как сделать его холодным. Существует четыре типа методов охлаждения, используемых в прецизионных системах охлаждения центров обработки данных, телекоммуникаций и других критически важных сред. Каждая технология охлаждения предназначена для адаптации к определенным условиям окружающей среды.

- Бесплатное охлаждение

Это самый экономичный вариант из всех четырех методов. Принцип основан на использовании низкотемпературного наружного воздуха или других естественных источников холода. Когда температура наружного воздуха достаточно низкая, система может напрямую подавать холодный наружный воздух в центр обработки данных или использовать теплообменники для передачи тепла от центра обработки данных к холодному наружному воздуху, избегая или сокращая работу механического холодильного оборудования для экономии энергии. Если ваша операционная среда находится в зоне с низкой температурой, например в местах, расположенных в высоких широтах или на высоте, система охлаждения с естественным охлаждением может значительно снизить коэффициент полезного действия (PUE) ваших центров обработки данных. - Воздушное охлаждение

Подходит для небольших и средних центров обработки данных с учетом расположения и места установки наружного блока. Он работает с помощью вентиляторов, втягивающих наружный воздух. Воздух проходит через змеевик испарителя, где хладагент поглощает тепло из воздуха. Затем нагретый хладагент поступает в змеевик конденсатора, где вентиляторы обдувают змеевик воздухом, чтобы отдать тепло в атмосферу. Охлажденный хладагент возвращается в испаритель, чтобы повторить процесс. Для некоторых мест со стабильным источником естественного холода выбор PAC с комбинацией технологий воздушного и естественного охлаждения является вполне разумным. - Водяное охлаждение

В системе с водяным охлаждением длина трубопровода циркуляции хладагента относительно невелика, что устраняет ограничение кондиционеров с воздушным охлаждением, в которых трубопровод хладагента не может быть слишком длинным из-за возможной потери давления и снижения эффективности. В данном случае вода выступает в качестве теплоносителя. Хладагент поглощает тепло в испарителе и превращается в высокотемпературный газ под высоким давлением. Затем он поступает в водоохлаждаемый конденсатор, где вода циркулирует по трубкам конденсатора. Вода поглощает тепло хладагента, охлаждая его и превращая обратно в жидкость. Затем нагретая вода направляется в градирню, где она отдает тепло воздуху и охлаждается для рециркуляции. Обратите внимание, что системы с водяным охлаждением не нуждаются в наружных конденсаторах, но обычно требуют градирен для эффективного отвода тепла. - Охлажденная вода

Системы PAC с охлажденной водой отлично подходят для крупномасштабных операций, эффективно обеспечивая постоянное охлаждение на больших расстояниях. Блок чиллера охлаждает воду до низкой температуры (охлажденная вода). Охлажденная вода подается по сети труб к вентиляционным установкам или охлаждающим змеевикам в центре обработки данных. Воздух в центре обработки данных проходит над этими змеевиками, и тепло воздуха поглощается охлажденной водой. Нагретая вода возвращается в чиллер и снова охлаждается, завершая цикл. Такая конструкция позволяет точно контролировать температуру и легко интегрируется с опциями естественного охлаждения, значительно повышая общую энергоэффективность центров обработки данных.

Во время переговоров с производителями они помогут вам определить наиболее подходящий метод охлаждения с учетом ваших географических условий. Хотя эти методы охлаждения могут удовлетворить большинство потребностей в охлаждении в критических условиях, если вам требуется более высокая эффективность и надежность, или если ваше оборудование имеет высокую плотность вычислений или нагрузку, вы можете рассмотреть следующие варианты Прецизионное кондиционирование воздуха с двумя источниками или Решения для жидкостного охлаждения центров обработки данных.

Проанализируйте условия окружающей среды

Тщательный анализ места установки системы охлаждения всегда был важен для минимизации затрат, снижения эффективности использования электроэнергии (PUE) в критических условиях, а также для продления срока службы оборудования. Как правило, все, что вы должны учитывать, - это влажность и температура. Исходя из этого, вы должны подумать о своем географическом положении, таком как широта, широта и высота.

- Температура

Ваше географическое положение - ключевой аспект, о котором мы часто думаем при выборе типа прецизионного кондиционера, поскольку он подразумевает, получает ли ваша система охлаждения стабильный источник холода от природы. Затем мы можем уточнить, можно ли использовать в вашем регионе системы естественного охлаждения и воздушного охлаждения, что означает возможность выбора более экономичных решений. Ваши широта и высота над уровнем моря - два ключевых аспекта, на которых нам следует сосредоточиться: - Широта

Более высокие широты обычно обеспечивают более стабильные низкие температуры, позволяя владельцам центров обработки данных использовать преимущества постоянного источника естественного холода, что может помочь снизить затраты на электроэнергию. В целом, когда широта превышает 30°, особенно в северных странах или регионах, использование систем естественного охлаждения становится более экономичным и целесообразным. - Высота

Как и в случае с широтой, на больших высотах температура воздуха ниже. На каждые 1000 метров набора высоты температура обычно снижается примерно на 6,5 °C. Такой эффект охлаждения особенно выгоден для центров обработки данных, поскольку обеспечивает стабильный и постоянный источник холодного воздуха.

В Колорадо (США), где многие центры обработки данных расположены на высоте более 2500 метров, используются методы естественного охлаждения, которые значительно снижают энергопотребление, достигая экономии энергии в 30-60% по сравнению с традиционными системами кондиционирования. Подобные внедрения демонстрируют, как использование высоты над уровнем моря может привести к значительному повышению операционной эффективности стратегий охлаждения. - Влажность

Как вы, возможно, знаете, испарение жидкостей поглощает тепло из окружающей среды. На этом принципе основаны прецизионные системы кондиционирования воздуха с водяным охлаждением, которые дополняют прецизионные системы с естественным охлаждением и воздушным охлаждением, особенно в тех случаях, когда расстояние между наружным и внутренним блоками является проблематичным.

Однако не в каждом месте можно выбрать конструкцию с водяным охлаждением. Одна из основных причин заключается в том, что на испарение существенно влияет уровень влажности окружающей среды. Высокая влажность может замедлить или даже остановить процесс испарения, что снижает эффективность систем водяного охлаждения.

В регионах с постоянно высокой влажностью производительность систем водяного охлаждения может быть снижена, что приведет к увеличению потребления энергии и снижению эффективности. Поэтому при выборе решений для прецизионного охлаждения с водяным охлаждением необходимо оценить местные условия влажности. Напротив, в районах с более низким уровнем влажности системы с водяным охлаждением могут работать более эффективно, обеспечивая значительную экономию энергии и повышение эффективности охлаждения.

( Вам может понравиться: Влажность как скрытый барьер: Почему это усложняет выбор прецизионных кондиционеров с водяным охлаждением )

Помимо того, что мы уже упомянули, есть несколько советов, которыми мы хотим с вами поделиться:

- ПервыйЕсли температура наружного воздуха превышает 45°C, требуется более мощный наружный блок, в частности, с большей холодопроизводительностью, чем наружный блок стандартного размера, согласованный с внутренним блоком при нормальных температурных условиях (обычно 25-35°C).

- ВторойЕсли температура наружного воздуха превышает 50°C, следует выбирать высокотемпературные системы кондиционирования, так как обычные устройства могут работать неэффективно или даже отключаться из-за перегрева.

- И последнее, но не менее важноеДля особых условий эксплуатации (например, прибрежные районы с сильным солевым туманом, нефтяные месторождения или регионы с агрессивными газами) антикоррозийная обработка наружного блока необходима для предотвращения повреждения его металлических компонентов и продления срока службы. В частности, в нефтегазовой отрасли необходимо предусмотреть дополнительные меры по обеспечению взрывозащиты, чтобы соответствовать стандартам безопасности и избежать риска пожара или взрыва, вызванного воспламеняющимися газами.

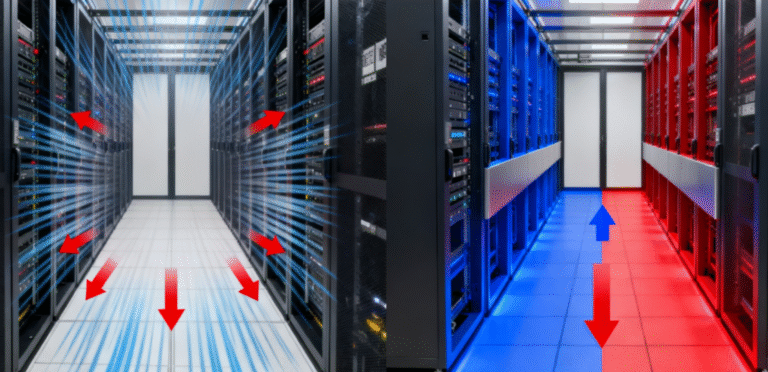

Понимание распространенных способов подачи воздуха

Различные модели прецизионных систем охлаждения могут иметь разные типы подачи воздуха. Например, подача воздуха вверх из диффузора обычно соответствует кондиционерам с меньшей холодопроизводительностью, в то время как в больших комнатных системах кондиционирования обычно используется либо восходящий, либо нисходящий поток. Для справки, существует пять методов:

- Восходящий поток из воздухораспределителя: При высоте потолка менее 300 мм расстояние подачи воздуха не должно превышать 8 метров.

- Восходящий поток из воздуховода: Обычно используется в зонах с меньшей тепловой нагрузкой и большим расстоянием подачи воздуха.

- Нисходящий поток из-под пола: Подходит для ситуаций, когда высота пола превышает 300 мм.

- Нисходящий поток от напольного вентилятора: Подходит для высоты пола более 450 мм, что позволяет увеличить расстояние подачи воздуха.

- Горизонтальный воздушный поток: Обычно используется в закрытых горячих и холодных проходах, а также в микромодулях.

Способы подачи воздуха иногда соответствуют различным требованиям к мощности охлаждения. Для небольших прецизионных систем охлаждения, таких как Soeteck 7.5-27.5kW Комнатный прецизионный кондиционерВоздухораспределитель обычно проектируется и устанавливается в корпус PAC, что означает, что вы не сможете исключить его из окончательного списка предложений. Однако для прецизионных кондиционеров, предназначенных для охлаждения больших помещений, методы подачи воздуха являются необязательными. Четкое указание требований к охлаждению поможет вашим поставщикам разработать для вас лучшее решение.

Уточните условия установки

Существует несколько аспектов условий установки прецизионного кондиционера, влияющих на решение проблемы охлаждения. Как правило, это расстояние между внутренним и наружным блоками, а также пространство места установки кондиционера. Основываясь на нашем опыте и знаниях, мы делимся некоторыми потенциальными причинами, на которые вам необходимо обратить внимание:

- Расстояние между внутренними и наружными блоками

Расстояние между внутренним и наружным блоками часто является "трудной задачей" для некоторых крупных проектов. Ведь слишком большое расстояние приведет к низкому давлению в линиях хладагента. Это может привести к недостаточному охлаждению, снижению эффективности и увеличению потребления энергии, что означает более высокую стоимость PUE. В этом случае система естественного охлаждения и система воздушного охлаждения, вероятно, не подойдут вам. Однако для PAC с водяным охлаждением и PAC с охлажденной водой это никогда не будет проблемой.

( Вам может понравиться: В чем разница между кондиционерами Precison с водяным охлаждением и охлажденной водой?) - Пространство для установки

Для выбора подходящей системы прецизионного охлаждения очень важно место установки. Для поддержания эффективности систем воздушного охлаждения необходимо достаточное пространство для наружной вентиляции и близость к внутренним блокам. Системы естественного охлаждения зависят от надлежащих путей поступления свежего воздуха и должны избегать загрязнения от источников тепла; ограниченное пространство может снизить их эффективность. Системам водяного охлаждения требуется наружное пространство для градирен и трубопроводов, а агрегатам с охлажденной водой - доступ к централизованным линиям охлаждения и достаточный зазор между потолком и полом.

Уточните требования к источнику питания

При выборе кондиционеров необходимо проверить требования к питанию, включая тип напряжения и частоту. В различных отраслях промышленности и регионах существуют свои стандарты мощности, что может повлиять на конструкцию прецизионных кондиционеров. Вот некоторые распространенные стандарты питания:

- Стандартное напряжение: 380 В, 60 Гц/50 Гц, 3-фазный

- Юго-Восточная Азия (Филиппины): 480 В, 50/60 Гц или 230 В, 50/60 Гц

- Большинство Страны Южной Америки (за исключением Аргентины и Чили): 208 В, 60 Гц

- США/Канада: 208 В, 60 Гц

Для производителей особые требования к электропитанию могут предполагать нестандартную комплектацию, поэтому важно сообщить эту информацию во время обсуждения, чтобы обеспечить успешную работу оборудования после поставки.

Заключение

Эффективное информирование производителей о требованиях к прецизионному охлаждению имеет решающее значение для обеспечения оптимальной производительности серверной комнаты. Сосредоточьтесь на предоставлении четких расчетов нагрузки охлаждения, указании методов отвода воздуха и подробном описании условий установки. Этим вы не только добьетесь лучшего понимания своих потребностей, но и улучшите сотрудничество с поставщиками. Подумайте о создании контрольного списка основных требований, чтобы упростить обсуждение и сохранить возможность масштабирования решений по охлаждению в будущем. Взаимодействие с экспертами может еще больше повысить вашу способность обеспечить эффективные и надежные системы охлаждения, отвечающие вашим производственным требованиям.

Контактная информация SOETECK

Наша компания занимается обслуживанием клиентов по всему миру, предлагая полный спектр решений в области прецизионных кондиционеров. От выбора продукции, производства и доставки до послепродажного обслуживания - мы располагаем обширной командой специалистов по продажам, технической поддержке, исследованиям и разработкам, а также послепродажному обслуживанию, обеспечивая удовлетворение ваших потребностей и гарантируя надежность вашего оборудования. Мы приглашаем вас связаться с нами, будь то предпродажная консультация, видеозвонок или инспекция на месте.

( Вам может понравиться: Архивы прецизионных кондиционеров Soeteck )