Ao planear o sistema de arrefecimento para um projeto de média a grande escala - quer se trate de um 1.000㎡ centro de dados que aloja centenas de servidores ou uma sala de controlo industrial de vários andares com equipamento sensível - uma pergunta deixa frequentemente os gestores e engenheiros das instalações bloqueados: Ambos arrefecido a água e água gelada os aparelhos de ar condicionado de precisão dependem da água para a permuta de calor, por isso, como escolher entre eles? A confusão centra-se normalmente nos custos ocultos: Será que uma escolha errada levará a taxas de manutenção elevadíssimas mais tarde? Ou será que a eficiência de arrefecimento fica aquém dos requisitos rigorosos de temperatura do equipamento?

Este artigo analisa os dois sistemas sob três ângulos principais: primeiro, explicando de forma simples os seus princípios fundamentais de funcionamento; segundo, comparando-os em 7 dimensões críticas (desde a lógica de troca de calor até à estrutura de custos); e finalmente, e fornece recomendações específicas para cada cenário e exemplos de casos. No final, terá um roteiro claro para evitar armadilhas comuns como “gastar demasiado na configuração inicial” ou “subestimar as contas de energia a longo prazo”.”

Se já leu o nosso blogue anterior sobre sugestões básicas para a seleção de ACs de precisão, Este artigo aprofunda as soluções baseadas na água, transformando o conhecimento geral em decisões práticas para o seu projeto específico.

Como funcionam: Foco na estrutura da unidade interior e na composição do sistema

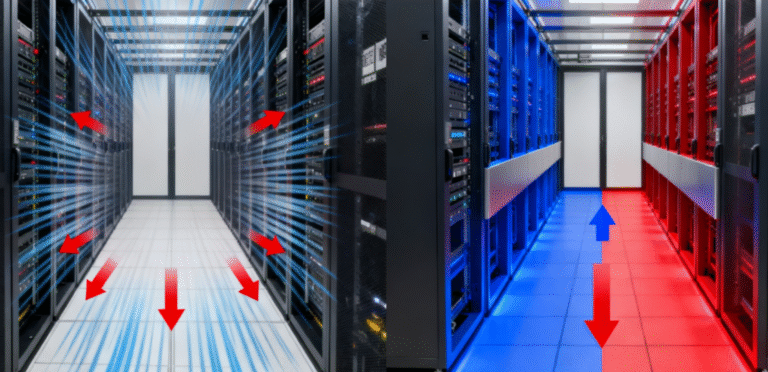

A diferença fundamental entre os ACs de precisão arrefecidos a água e os ACs de precisão arrefecidos a água reside na sua conceção da unidade interior e vias de dissipação de calor. Vamos analisar os seus princípios operacionais e componentes principais.

1. ACs de precisão arrefecidos a água

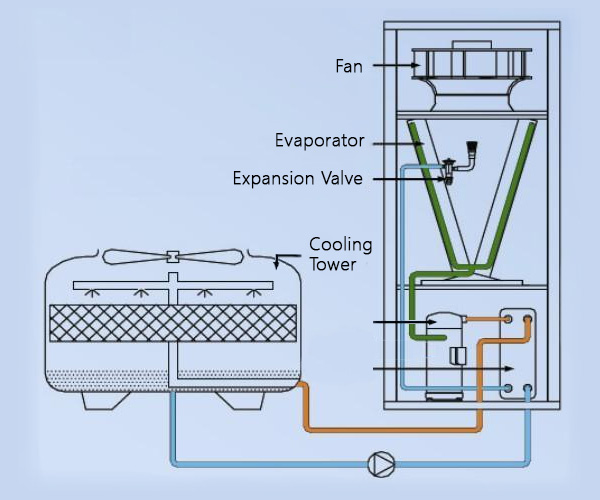

Os AC de precisão arrefecidos a água são categorizados como “sistemas de expansão direta (DX)” com componentes de permuta de calor arrefecidos a água integrados. As suas unidades interiores contêm circuitos de refrigerante e a rejeição de calor depende de fontes de água externas (por exemplo, torres de arrefecimento).

Estrutura do núcleo da unidade interior

A unidade interior de um AC de precisão arrefecido a água é um módulo de arrefecimento autónomo com dois componentes principais:

- Bobina do evaporador: Arrefece diretamente o ar interior. À medida que o ar quente passa pela serpentina, o refrigerante no interior absorve o calor, passando de líquido a gás de alta temperatura e alta pressão - é aqui que ocorre o arrefecimento efetivo do espaço.

- Permutador de calor arrefecido a água: Um permutador de calor de placas ou de casco e tubo incorporado (caraterística distintiva essencial). O fluido frigorigéneo quente flui através deste permutador, libertando calor para a água de arrefecimento que circula no seu interior. Esta arrefece o fluido frigorigéneo, que volta a entrar no evaporador para continuar o ciclo.

Composição completa do sistema

O sistema estende-se para além da unidade interior para incluir:

- Fonte de água de arrefecimento: Pode ser o sistema de água de arrefecimento centralizado de um edifício, uma torre de arrefecimento ou um poço. Em circuitos fechados com refrigeradores secos externos, a água de refrigeração é frequentemente uma mistura resistente ao gelo de água e glicol (substituindo os refrigerantes tradicionais para transferência de calor).

- Bomba de água e tubagem: Faz circular a água de arrefecimento entre o permutador de calor da unidade interior e o dispositivo de rejeição de calor (por exemplo, torre de arrefecimento).

- Dispositivo de rejeição de calor: Normalmente, uma torre de arrefecimento (para troca de calor húmida, em que o ar e a água entram em contacto direto) ou um arrefecedor seco (para troca de calor seca, evitando a evaporação da água).

Lógica operacional

- O evaporador interior absorve o calor da divisão, convertendo o fluido frigorigéneo em gás.

- O refrigerante quente flui para o permutador de calor arrefecido a água incorporado, transferindo o calor para a água de arrefecimento.

- A água de arrefecimento aquecida é bombeada para uma torre de arrefecimento ou para um arrefecedor a seco, libertando o calor para o ambiente externo.

- O refrigerante arrefecido (agora líquido) regressa ao evaporador, repetindo o ciclo.

2. ACs de precisão de água refrigerada

Os ACs de precisão com água refrigerada são “dispositivos de arrefecimento terminal” que dependem inteiramente de um fornecimento externo de água refrigerada. As suas unidades interiores não têm circuitos de refrigeração ou compressores, o que as torna mais simples em termos de estrutura, mas dependentes de uma fonte de frio centralizada.

Estrutura do núcleo da unidade interior

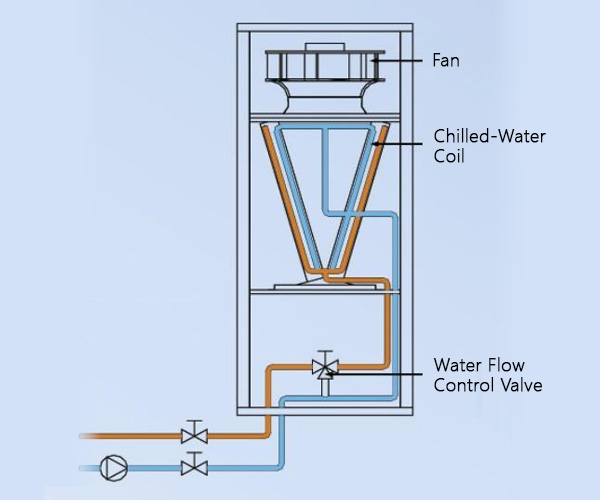

A unidade interior (unidade terminal) de um AC de precisão de água refrigerada foi concebida para troca de calor indireta, com três componentes principais:

- Serpentina de água refrigerada: Uma bobina metálica através da qual flui água refrigerada a baixa temperatura (normalmente cerca de 15℃ para grandes centros de dados). O calor do ar interior é absorvido pela água refrigerada à medida que o ar passa sobre a bobina, arrefecendo o espaço.

- Ventilador: Força o ar interior sobre a serpentina de água refrigerada, assegurando uma troca de calor eficiente e distribuindo o ar refrigerado por toda a divisão.

- Válvula de controlo da água: Regula o caudal de água refrigerada com base nas exigências de temperatura interior, ajustando a capacidade de refrigeração de forma dinâmica.

Composição completa do sistema

O sistema de água gelada é uma rede distribuída que requer múltiplos componentes coordenados:

- Fonte externa de água refrigerada: Uma instalação central de resfriamento que resfria a água até a temperatura necessária (por exemplo, 15 ℃).

- Bomba de água gelada e rede de tubagens: Fornece água refrigerada do refrigerador para as unidades interiores e devolve água quente para ser novamente arrefecida.

- Equipamento de apoio: Inclui permutadores de calor de placas (para otimização da transferência de calor), torres de arrefecimento (para dissipar o calor do chiller) e bombas de água de arrefecimento (para o circuito de rejeição de calor do chiller).

Lógica operacional

- O chiller central produz água refrigerada a baixa temperatura e distribui-a a todas as unidades interiores através de tubos.

- O ar interior é soprado sobre a serpentina de água refrigerada, sendo o calor transferido para a água refrigerada.

- A água refrigerada, agora aquecida, flui de volta para o refrigerador, onde é novamente arrefecida.

- A capacidade de arrefecimento da unidade interior varia em função de factores como a temperatura da água à entrada/saída e as condições do ar - a produção pode diferir várias vezes em diferentes condições de funcionamento.

Principais diferenças: Unidades interiores e caraterísticas do sistema

O quadro seguinte compara os dois sistemas em dimensões críticas, salientando as diferenças em termos de estrutura, desempenho e aplicabilidade:

| Dimensão de comparação | AC de precisão arrefecido a água | AC de precisão de água refrigerada |

|---|---|---|

| 1. Componentes principais da unidade de interior | Bobina do evaporador, permutador de calor arrefecido a água incorporado (placa/concha e tubo), circuito de refrigeração | Serpentina de água refrigerada, ventilador, válvula de controlo da água (sem refrigerante ou compressor) |

| 2. Caminho de troca de calor | Ar ambiente → Refrigerante (evaporador) → Água de arrefecimento (permutador de calor incorporado) → Rejeição externa de calor | Ar ambiente → Água refrigerada (serpentina) → Refrigerador central → Rejeição externa de calor |

| 3. Estabilidade da capacidade de arrefecimento | Fixo (determinado pela conceção do circuito do refrigerante) | Variável (depende da temperatura da água refrigerada, das condições do ar - pode variar várias vezes) |

| 4. Dependência do sistema | Funcionamento independente (apenas necessita de uma fonte de água de arrefecimento) | Dependente da instalação central de refrigeração (não pode funcionar isoladamente) |

| 5. Eficiência energética | Mais elevado do que os sistemas arrefecidos a ar; eficiência de permuta de calor estável | Depende da eficiência do chiller; a eficiência global do sistema é elevada para aplicações em grande escala |

| 6. Requisitos de instalação | Necessita de tubagem de água de arrefecimento (que liga a unidade interior ao dispositivo de rejeição de calor) | Necessita de uma rede de tubagem de água refrigerada (ligação ao refrigerador central) |

| 7. Cenários aplicáveis | Locais com sistemas de água de arrefecimento centralizados; cargas de arrefecimento médias (zona única) | Grandes centros de dados ou instalações multi-zona; integrados com instalações centrais de refrigeração |

Qual escolher? Orientação específica para o cenário

O sistema “certo” depende da dimensão, localização, orçamento e objectivos a longo prazo do seu projeto. Abaixo estão os cenários mais comuns em que um sistema supera o outro - além de erros a evitar.

1. Escolha arrefecimento a água se:

- O seu projeto é pequeno e localizado: Por exemplo, uma sala de servidores de 50-300㎡ ou uma sala de controlo industrial de um piso. O custo inicial mais baixo e a configuração simples significam que pode começar a funcionar rapidamente sem investir demasiado.

- As unidades interior e exterior estão próximas (≤30m): Se a sua torre de arrefecimento puder ser colocada perto da unidade interior (por exemplo, num telhado próximo ou num terreno adjacente), evitará perdas de eficiência resultantes de longas linhas de refrigerante.

- Tem um orçamento inicial apertado (e menor sensibilidade aos custos de manutenção): Para projectos de curto prazo (como um laboratório de testes temporário) ou equipas com pessoal de manutenção interno, os custos contínuos mais elevados são mais fáceis de gerir do que o elevado preço inicial de um chiller.

2. Selecione Água refrigerada se:

- O seu projeto é grande ou disperso: Para um centro de dados com mais de 1.000㎡, um hospital com vários laboratórios ou uma instalação de fabrico de vários andares, a rede de tubos do chiller pode arrefecer todas as áreas a partir de uma unidade central - eliminando a necessidade de vários sistemas independentes.

- A eficiência energética e as poupanças a longo prazo são importantes: Se o seu sistema funcionar 24 horas por dia, 7 dias por semana (como um centro de dados na nuvem), o elevado EER do chiller e a integração de arrefecimento livre compensarão. A maioria dos clientes recupera o custo inicial mais elevado no prazo de 3 a 5 anos através de facturas de energia e manutenção mais baixas.

- Não tem espaço exterior (ou necessita de refrigeração a longa distância): Em áreas urbanas densas onde não é viável uma torre de arrefecimento (por exemplo, uma sala de servidores na cave de um edifício de escritórios no centro da cidade), os tubos de água refrigerada podem percorrer centenas de metros sem perder eficiência.

3. Erros comuns a evitar

- Erro 1: “Grande projeto = tem de utilizar água refrigerada”: Se o seu grande projeto estiver dividido em áreas independentes e desconectadas (por exemplo, três salas de servidores de 400㎡ separadas em edifícios diferentes), vários sistemas arrefecidos a água podem ser mais baratos do que um único chiller com tubagens longas e dispendiosas.

- Erro 2: “A refrigeração a água é mais fácil de manter”: Não negligencie os riscos de humidade. Em zonas costeiras ou de elevada humidade, as torres de arrefecimento desenvolvem algas e incrustações rapidamente - entupindo os condensadores e causando tempos de inatividade inesperados. A química estável da água refrigerada evita esta situação.

- Erro 3: “A água refrigerada é demasiado cara à partida”: Calcule sempre o ROI a longo prazo. Um chiller pode custar 50% mais inicialmente, mas se reduzir a sua fatura anual de energia em $12.000 (como no estudo de caso abaixo), irá poupar dinheiro ao longo do tempo.

Exemplos de casos: Lógica de seleção para sua referência

Para tornar a lógica de seleção mais tangível, eis dois exemplos de casos ilustrativos que se alinham com cenários de projectos comuns. Reflectem factores típicos de tomada de decisão (orçamento, espaço, escala) para o ajudar a adaptá-los às suas próprias necessidades.

1. Sistema arrefecido a água para uma sala de controlo de fábrica de 300㎡

- Antecedentes do projeto: Uma fábrica planeia arrefecer uma sala de controlo de 300㎡ que alberga equipamento para monitorizar linhas de montagem. A sala é adjacente a uma área externa vazia, e o projeto tem um orçamento inicial de $50.000.

- Porquê arrefecimento a água?: Um sistema de água gelada custaria mais de $75.000 (incluindo o chiller e a tubagem), excedendo o orçamento. O espaço exterior pode acomodar uma pequena torre de arrefecimento e a distância entre as unidades interiores e exteriores é de apenas 15 m - ideal para uma instalação arrefecida a água. Além disso, a fábrica tem uma equipa de manutenção interna capaz de efetuar limpezas regulares da torre.

- Resultados esperados: O sistema mantém a temperatura ambiente a 22±1℃ (cumprindo os requisitos do equipamento) com um custo anual de energia estimado em ~$8,000. A manutenção mensal demora 2-3 horas, que podem ser geridas pela equipa interna da fábrica.

2. Sistema de água gelada para um centro de dados urbano de 1.500㎡

- Antecedentes do projeto: Uma empresa de tecnologia pretende construir um data center de 1.500㎡ em três andares de um prédio de escritórios no centro da cidade. O edifício não tem espaço exterior para torres de arrefecimento e o sistema tem de funcionar 24 horas por dia, 7 dias por semana.

- Porquê água gelada?: Um sistema de arrefecimento a água é inviável devido à falta de espaço na torre, e várias unidades de arrefecimento pequenas seriam ineficientes. O chiller é instalado na cave do edifício, com tubos de ligação às serpentinas de arrefecimento em cada piso. A refrigeração livre é integrada para reduzir o consumo de energia no inverno.

- Resultados esperados: Prevê-se que o PUE (Power Usage Effectiveness) do centro de dados desça para 1,2 (bem abaixo da média da indústria de 1,5), com um custo anual de energia de $36,000-$12,000 menos do que uma alternativa arrefecida a água. Prevê-se que o custo inicial mais elevado do chiller seja recuperado no prazo de 4 anos.

Conclusão e próximas etapas

1. Principais conclusões

Para resumir numa frase: Os sistemas arrefecidos a água são para projectos “pequenos, próximos e com orçamento apertado”; os sistemas de água refrigerada são para projectos “grandes, dispersos e centrados na eficiência”. A principal diferença reside na sua lógica de permuta de calor - direta vs. indireta - que se repercute em todos os aspectos de custo, instalação e desempenho.

Para uma verificação rápida, utilize este fluxo de decisão simplificado:

- O seu projeto é ≤500㎡ (pequeno) ou ≥1000㎡ (grande)?

- As unidades interiores e exteriores estão separadas por uma distância ≤30 m (arrefecimento a água) ou precisam de estar mais afastadas (arrefecimento a água)?

- Dá prioridade às poupanças iniciais (arrefecimento a água) ou à eficiência a longo prazo (água refrigerada)?

2. Próximos passos

- Se ainda não tem a certeza: Reúna estes detalhes e contacte uma equipa técnica: dimensão do projeto (㎡), número de áreas a refrigerar, distância interior-exterior, orçamento (inicial vs. longo prazo) e disponibilidade de espaço exterior. Isto permitirá que os especialistas adaptem uma solução às suas necessidades.

- Saiba mais: Para obter dicas sobre como manter o seu sistema a funcionar sem problemas, leia o nosso blogue “Dicas de manutenção de AC de precisão: Prolongar a vida útil e reduzir os custos”. Para obter informações mais detalhadas sobre como escolher o AC de precisão correto para ambientes críticos (incluindo considerações sobre refrigeração gratuita), consulte o nosso guia sobre Aspectos-chave para a seleção de CA de precisão em ambientes críticos.

- Obter apoio: Em SOETECK, Na nossa empresa, concebemos, instalamos e mantemos ambos os sistemas em mais de 300 projectos de média a grande dimensão (desde centros de dados a hospitais). A nossa equipa pode ajudá-lo a comparar custos, avaliar o seu espaço e criar uma solução que se adeqúe aos seus objectivos - sem engenharia excessiva, sem taxas ocultas.

Quer opte por um sistema de arrefecimento de precisão arrefecido a água ou a água gelada, o objetivo é o mesmo: um arrefecimento fiável e eficiente que mantenha o seu equipamento a funcionar - e os seus custos sob controlo. Com o sistema certo, evitará as dores de cabeça do tempo de inatividade, gastos excessivos e objectivos de eficiência não atingidos.