在人工智能、边缘计算和全天候数字化运营时代,服务器机架越来越密集,温度也越来越高。单个高密度机架(10 千瓦以上)产生的热量相当于一个小型空间加热器,而如果没有量身定制的 服务器机架冷却解决方案, 这种集中的热负荷会导致热点、服务器节流、硬件故障和代价高昂的停机时间(根据 Gartner 的数据,平均每小时停机时间为 $100,000)。.

与针对整个空间的一般机房冷却不同,服务器机架冷却解决方案的重点是热源:机架本身。它旨在解决密集 IT 设备所面临的独特挑战--热量分布不均、气流受限,以及需要在不浪费能源的情况下保护敏感元件。下面,我们将介绍 7 种专家支持的策略,用于设计、实施和优化服务器机架冷却解决方案,以满足您的密度需求并提供长期效率。.

1.根据机架密度匹配服务器机架冷却解决方案

有效机架冷却的首要原则是根据机架的热负荷调整解决方案--密度决定设计。机架通常按热量输出分类,每种热量输出需要不同的服务器机架冷却解决方案:

-低密度(≤5 千瓦): 常见于小型企业或办公室服务器机柜。一个紧凑型精密空气冷却器(安装在机架上或附近),甚至一个优化的机房冷却系统(配以适当的气流)就足够了。.

-中密度(5-10 千瓦): 用于不断增长的中型市场 IT 基础设施。需要有针对性的解决方案,如基于行的精密冷却系统(安装在机架之间的设备)或直接向机架吹送冷空气的机架式无管道系统。.

-高密度(10-20 千瓦): 存在于主机代管设施或人工智能/ML 环境中。需要先进的空气冷却(如带热通道隔离的闭环机架冷却)或入门级液体冷却(冷板)。.

-超高密度(≥20 千瓦): 专用于高性能计算集群或数据密集型工作负载。需要液体冷却(浸入式或直接到芯片),以处理极端热负荷。.

例如

一家拥有 4 个中等密度机架(每个 8 千瓦)的金融科技初创企业最初使用的是普通机房空调设备,导致机架顶部出现持续的热点(28°C)。在改用基于行的精确冷却系统(有针对性的服务器机架冷却解决方案)后,所有机架的温度都稳定在 22°C,冷却能耗减少了 23%。.

2.在空间有限的环境中优先考虑机架式冷却系统

对于空间有限的服务器机房或边缘设施(如零售店后厨、小型办公室壁橱等)而言,机架式服务器机架冷却解决方案可改变游戏规则。这些结构紧凑的设备可直接安装在机架上(顶部、底部或侧面),无需占用地面空间,并能在需要的地方提供冷空气。.

机架式解决方案的主要类型:

-机架式精密空气冷却器: 独立式设备从机架吸入热空气,通过制冷剂冷却,然后吹回冷通道。是中低密度机架(≤10 千瓦)和狭小空间的理想选择。.

-机架式液体冷却系统: 安装在服务器 CPU/GPU 上的紧凑型冷板或微通道装置,可直接吸收热量。适用于中高密度机架(8-15kW)和空气冷却效率较低的环境。.

优势

一家地区医疗诊所有一个 2 机架的服务器机柜(总负载 6 千瓦),使用机架式精密空气冷却器取代了笨重的落地式设备。该解决方案腾出了 30 平方英尺的空间,降低了噪音(对临床环境至关重要),并保持了 ±1°C 的温度精度,确保病人数据服务器保持在线。.

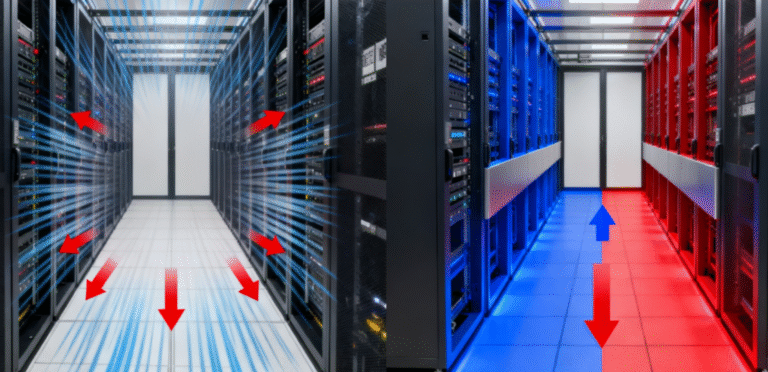

3.为高密度机架实施闭环冷却

高密度机架(10 千瓦以上)会产生大量热量,标准的空气冷却无法跟上,除非使用闭环服务器机架冷却解决方案。闭环系统将机架的供气与机房的其他部分隔离,防止冷热空气混合(造成效率低下和热点的 #1 原因)。.

如何使用

-冷空气通过风扇或管道在机架内(或机架周围的小封闭区域)循环。.

-热空气直接排入房间的回风系统或专用热通道,绝不会再循环回冷空气供应系统。.

最适合

主机代管设施、采用混合密度机架的数据中心或任何存在空气混合问题的环境。与冷热通道隔离装置搭配使用,可实现最高效率。.

案例研究:

达拉斯的一家主机代管服务提供商拥有 12 个高密度机架(每个 15 千瓦),尽管配备了强大的室内冷却系统,但仍存在热点(30°C)。在安装了带隔离板的闭环机架冷却系统后,他们将机架温度降低到 21°C,冷却能耗减少了 31%,并能在同一空间内增加 2 个机架(这得益于热管理的改善)。.

4.为超高密度机架采用液体冷却技术

当机架密度超过 20kW 时,空气冷却就会遇到瓶颈--液体冷却成为唯一可行的服务器机架冷却解决方案。液体的导热效率是空气的 4 倍,因此非常适合超高密度工作负载(如人工智能训练、高性能计算、加密挖矿)。.

用于机架的主要液冷型号:

-直接芯片(冷板)冷却: 连接 CPU、GPU 和其他热组件的金属板。冷冻液体在金属板上循环,吸收热量并将其带入热交换器。适用于 15-30kW 机架。.

-浸入式冷却: 服务器完全浸没在不导电的介电流体中,这种流体可以吸收热量。液体通过热交换器冷却,无需风扇。适用于 30kW 以上机架和极端环境。.

例如

一家科技巨头的人工智能研究实验室为 8 个超密集机架(每个 35kW)采用浸入式冷却,为 GPU 集群供电。与空气冷却相比,服务器机架冷却解决方案减少了 47% 的冷却能耗,完全消除了热点,并使实验室能够在相同的空间内容纳多 2 倍的服务器。.

5.优化机架布局和气流,最大限度地提高冷却效率

即使是最好的 服务器机架冷却解决方案 如果气流管理不当,就会出现故障。我们的目标是确保冷空气到达服务器进气口,热空气迅速排出--没有混合,没有停滞。.

专家气流提示

机架方向: 将机架排列在冷热通道中--服务器面向冷通道(吸入冷空气),将热空气排入热通道。使用隔离板密封通道。.

消隐板: 在空的机架槽中安装隔板,防止冷空气从未用过的空间泄漏(这是一个常见的疏忽,会浪费 15-20% 的冷却能力)。.

电缆管理 使用垂直电缆整理器,使电缆远离气流通道--杂乱的机架会阻碍空气流通并产生热点。.

机架高度: 将机架抬离地面 6-12 英寸,以便于地板下的空气分配(对于基于房间或行的冷却系统至关重要)。.

结果

芝加哥的一家物流公司将 10 个机架重组为冷热通道,增加了隔板,并整理了电缆。他们现有的服务器机架冷却解决方案(基于行的精密冷却)效率提高了 27%,热点温度从 29°C 降至 23°C。.

6.为服务器机架冷却解决方案增加冗余

对于任务关键型机架(例如,为客户交易、医疗记录或工业系统供电的机架)而言,冗余是不可或缺的。如果服务器机架冷却解决方案没有备份,一旦某个设备出现故障,就会导致灾难性的停机。.

冗余选项:

N+1 冗余: 每需要 N 台冷却器,就多安装一台。例如,如果 2 个机架式冷却器可处理一个 10 千瓦的机架,则应增加第 3 个作为备用。.

双电源: 确保冷却装置有双电源(如主电网 + UPS),以便在停电时保持运行。.

跨区冷却: 对于行式系统,可将机架连接到多个冷却装置上,这样如果一个冷却装置出现故障,其他冷却装置就能承担起负荷。.

案例举例:

一家地区性银行的核心交易机架(12 千瓦)采用了 N+1 服务器机架冷却解决方案(2 个活动冷板单元 + 1 个备用单元)。当一个主动单元的压缩机发生故障时,备用单元在 3 秒钟内启动--没有温度骤升,没有停机时间,对客户交易没有任何影响。.

7.利用智能监控主动优化服务器机架冷却解决方案

现代服务器机架冷却解决方案并不是 “设置好了就不管了”--它们是可以通过实时数据进行优化的智能系统。智能监控工具可帮助您跟踪性能、识别效率低下的问题,并在问题导致停机之前加以预防。.

需要寻找的关键监控功能:

实时温度/湿度跟踪:监控机架级别(而不仅仅是房间)的情况,及早发现热点。.

能源使用指标: 跟踪冷却解决方案每个机架消耗多少能源,以发现浪费。.

预测性维护警报: 人工智能驱动的工具可分析组件数据(如风扇速度、压缩机性能),在潜在故障(如过滤器堵塞、风扇失灵)影响冷却之前向您发出警报。.

遥控器: 从中央控制面板调整冷却设置(如风扇速度、温度设定点),这对边缘机架或远程设施至关重要。.

例如

一家拥有 50 个分布式边缘机架的云提供商在其服务器机架冷却解决方案中使用了智能监控平台。该系统检测到一个 8 千瓦机架的气流下降(由过滤器堵塞引起),比导致过热的时间提前了 14 天。团队在一次定期访问中更换了过滤器,避免了计划外停机,并将冷却装置的使用寿命延长了 2 年。.

结论:有针对性的服务器机架冷却解决方案是现代 IT 的不二选择

随着服务器机架越来越密集,工作负载要求越来越高,"一刀切 "的冷却方式已经不能满足需要。量身定制的 服务器机架冷却解决方案-与您的密度、空间和可靠性需求相匹配,将集中热量从负担变为可应对的挑战。.

无论您运行的是小型办公机架还是超密集高性能计算集群,上述策略都证明,有效的机架冷却不仅仅是 “更多冷空气”,而是在正确的时间、正确的地点提供正确的冷却。通过投资有针对性的解决方案,并通过气流管理、冗余和智能监控对其进行优化,您可以保护硬件、降低成本并确保不间断运行。.

准备完善您的设置?我可以根据您的机架密度、空间限制和预算,帮助您创建定制的服务器机架冷却解决方案评估,找出差距并推荐最佳系统。如果您想深入了解,请告诉我。.