As AI computing power surges and energy storage systems develop towards high power density, Liquid Cooling Solution has become the optimal thermal management choice for critical scenarios such as data centers, energy storage stations, and EV fast charging. Compared with traditional air cooling, it achieves 3-5 times higher heat dissipation efficiency, reduces energy consumption by 20-30%, extends equipment lifespan by 50%+, and supports ultra-high power density up to 100kW+ per cabinet. Its two mainstream technical routes—cold plate and immersion cooling—respectively meet the needs of stock transformation and future high-density computing, creating significant operational value and carbon reduction benefits for enterprises.

Why Liquid Cooling Solution Outperforms Traditional Air Cooling?

With the rapid iteration of high-performance chips and the continuous improvement of system power density, traditional air cooling technology has reached its bottleneck in thermal management. Liquid Cooling Solution, relying on the superior thermal conductivity of liquid media, has become a necessary choice for breaking through the heat dissipation limit. The following comparative data clearly demonstrates its core advantages:

| Evaluation Metrics | Liquid Cooling Solution | Traditional Air Cooling |

| Heat Dissipation Efficiency | 3-5 times higher, supporting up to 200W/cm² heat flux density | Limited by air thermal conductivity, only suitable for low-power density |

| Energy Consumption | Reduces node-level power consumption by 16% on average; PUE can be as low as 1.02 | High fan energy consumption; data center PUE is usually 1.4-1.6 |

| Equipment Lifespan | 8-12 years, reducing failure rate by 80%+ | 5-7 years, easily affected by dust and temperature fluctuations |

| Power Density Support | Up to 100kW+ per cabinet, adapting to AI and supercomputing needs | Only 5-10kW per cabinet, difficult to meet high-density requirements |

| Operational Cost | Annual energy cost savings of $2.25 million for 2,000-node data centers | High long-term energy and maintenance costs |

Relevant tests show that in NVIDIA GPU systems, liquid cooling can maintain the GPU temperature at 46-54°C, while air cooling leads to a temperature range of 55-71°C. This stable temperature control enables liquid-cooled systems to deliver up to 17% higher computational throughput during stress tests, which is crucial for AI model training and high-performance computing tasks .

Two Mainstream Technical Routes of Liquid Cooling Solution

Liquid Cooling Solution mainly includes two technical routes: cold plate liquid cooling and immersion liquid cooling. Enterprises can choose the appropriate solution according to their business needs, power density, and budget constraints:

Cold Plate Liquid Cooling

Cold plate liquid cooling achieves targeted heat dissipation by attaching custom metal cold plates to core heat-generating components such as CPUs and GPUs. It adopts a “local liquid cooling + global air cooling” hybrid architecture, which does not require subversive modifications to the existing server structure and has strong compatibility.

- Market Position: Currently accounts for 80% of the liquid cooling market, being the mainstream choice for commercialization .

- Core Advantages: Low transformation cost (only 30%-50% of immersion cooling), mature technology, and easy maintenance. It can reduce data center PUE to below 1.2, fully meeting the requirements of green data center policies.

- Applicable Scenarios: General cloud computing, enterprise-level data centers, stock transformation projects, and scenarios with power density of 15-30kW per cabinet.

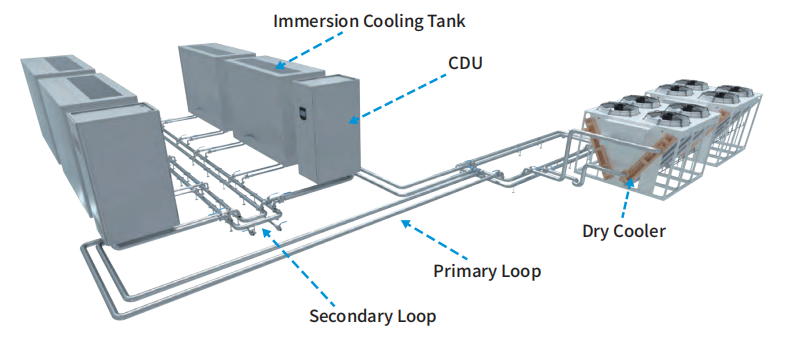

Immersion Liquid Cooling

Immersion liquid cooling submerges the entire server in insulating coolant (such as mineral oil and fluorinated liquid), achieving full-area heat dissipation through natural convection or boiling of the liquid. Although it currently accounts for only about 20% of the market, it is regarded as the core direction for ultra-high power density scenarios due to its extreme heat dissipation potential.

- Core Advantages: Heat dissipation efficiency is 5 times higher than that of cold plate liquid cooling; it can support power density of 50-100kW per cabinet, and the PUE can be as low as 1.03-1.05. It can completely eliminate fans, reducing equipment power consumption by 5%-15% and avoiding environmental impacts such as dust and humidity .

- Cost Trend: With the localization of coolants and large-scale production, the cost is expected to be reduced by 50% by 2030, and the market share is expected to rise to 40% .

- Applicable Scenarios: Supercomputing centers, AI training clusters, quantum computing, and other scenarios with ultra-high power density requirements.

Key Application Scenarios of Liquid Cooling Solution

Liquid Cooling Solution has been widely used in multiple fields driven by the dual demands of high power density and energy conservation. The following are the core application scenarios:

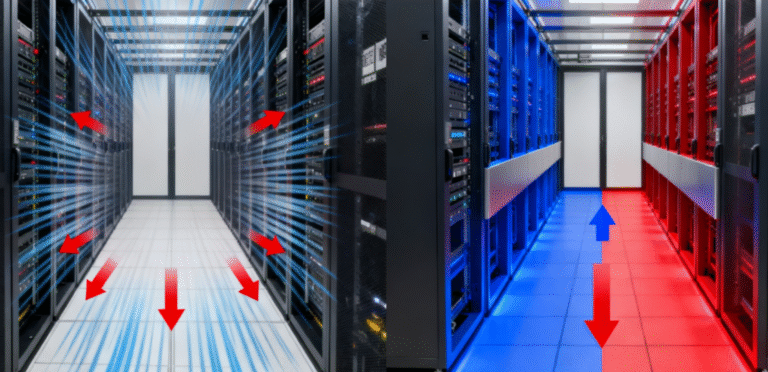

Data Centers

As the power density of data center cabinets soars to 40kW+ (some high-end racks even exceed 140kW), air cooling can no longer meet the heat dissipation needs. Liquid cooling has become a mandatory choice for new data centers. For example, Thermax’s adiabatic dry cooling tower liquid cooling system was applied in a data center in Pune, India, achieving stable cooling water temperature control (46°C inlet / 35°C outlet) and ensuring the stable operation of supercomputers while saving 80% of water resources .

Energy Storage Systems

Liquid cooling solves the heat dissipation problem of energy storage systems under high power density. It can control the temperature difference of battery modules within ±3°C, extending the cycle life to 15,000 times. In grid-level large energy storage stations, the immersion liquid cooling system adopted in the Qinghai Gonghe energy storage project achieves a PUE of 1.05 and saves 5 million yuan in electricity fees annually . The global liquid cooling energy storage market is growing at a high speed, with the Chinese market scale expected to reach 23.63 billion yuan in 2024 and exceed 102 billion yuan in 2027 .

EV Fast Charging

Fast charging stations generate a lot of heat in a short time, which affects battery safety and lifespan. Liquid cooling ensures precise temperature control during fast charging, improving charging efficiency and battery health. It has become a standard configuration for high-power fast charging stations.

How to Choose the Right Liquid Cooling Solution?

When selecting a Liquid Cooling Solution, enterprises need to comprehensively consider the following factors to achieve the optimal balance between performance and cost:

- Power Density Requirements: Choose cold plate liquid cooling for scenarios with power density below 30kW per cabinet; choose immersion liquid cooling for scenarios above 50kW per cabinet.

- Budget and Transformation Cost: For stock data center transformation with limited budget, cold plate liquid cooling is more cost-effective; for new high-density computing projects, immersion liquid cooling can be deployed in advance to reserve computing power potential.

- Operational Maintenance Capabilities: Cold plate liquid cooling has lower maintenance requirements and is compatible with existing O&M systems; immersion liquid cooling requires professional teams for coolant management and equipment maintenance.

- Policy and Carbon Reduction Goals: If enterprises need to meet green data center certification or carbon neutrality targets, immersion liquid cooling with lower PUE is more in line with long-term development needs.

Market Trends and Future Outlook

Driven by AI computing power construction and global energy transformation, the global liquid cooling market is in a high-growth period. The market scale is expected to reach 12 billion US dollars in 2025 and 31.2 billion US dollars in 2030, with a compound annual growth rate exceeding 20% . The future development will show two main trends:

- Dual-Route Parallel Development: Cold plate liquid cooling will remain the mainstream in the short term (2025-2030), while immersion liquid cooling will achieve rapid growth in high-density scenarios. Most leading enterprises will adopt a “cold plate large-scale deployment + immersion frontier exploration” strategy .

- Accelerated Localization and Cost Reduction: Core components such as domestic coolants and liquid cooling pumps are constantly breaking international monopolies. The cost of domestic coolants is 40% lower than that of imported products, which will drive the large-scale popularization of liquid cooling solutions.

Final Summary: Liquid Cooling Solution is not just a replacement for traditional air cooling, but a core supporting technology for the development of high-density computing and sustainable energy. With the continuous maturity of technology and the decline of cost, it will be widely applied in more fields. Enterprises that layout liquid cooling technology in advance will gain significant competitive advantages in the era of digital transformation and energy transition.

Liquid Cooling FAQs

• Deionized water (affordable, add corrosion inhibitors)

• Pre-mixed coolants (convenient, pre-formulated)

• Dielectric fluids (non-conductive, safer but pricier)